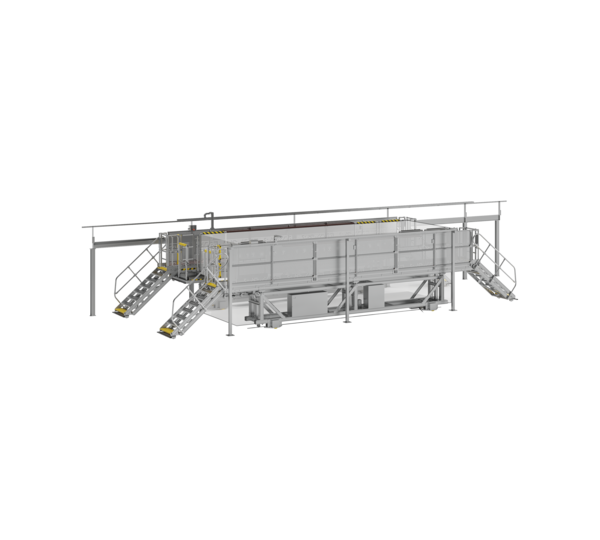

Self-propelled electric work platform

Specifications

Information

- Platform length: 8000mm

- Platform width: 800mm + extension: 350mm

- Platform height: 1420mm–1850mm (adjustable range: 430mm, continuously adjustable)

- Platform surface: grooved aluminum / extension: ribbed aluminum sheet

- Cross extension: on the longitudinal side using linear motors

- Height adjustment: stepless by means of hand cranks and threaded spindles

- Drive: speed 0.2m/min - 16m/min continuously adjustable

- 4 castors 230xØ50mm with polyurethane tread, mobile in guide rail (firmly anchored to the floor)

- Surface load: 150 kg/m²

- Total load: 500 kg

- Step load: 150 kg

Client's Request and Task

Our task was to develop a work platform that facilitates the assembly of roofs and the conversion of vehicles into campers and caravans. The platform needed to be individually adaptable to various vehicle types, offer protection against damage, and enable ergonomic working for employees.

- Assembly and conversion of vehicles on the platform

- Individual adaptability to the height and width of different vehicles

- Protection of vehicles from damage

- Synchronization of the platform with vehicle movements

- Integration of media connections on the platform

- Individually adjustable speeds for the forward and backward movement of the work platform

- Maximum occupational safety and user-friendliness

Our Solution

Work Platform Concept

Our solution consists of two self-propelled electric work platforms, also known as stages. Each stage is individually adjustable in width, height, and speed, allowing for effortless servicing of different vehicle types.

Adjustable Speed, Width, and Height

The working speed of the platforms is individually adjustable to ensure an optimal production flow. The working height can be manually adjusted via an ergonomically placed hand crank and threaded spindles. This feature enables various assembly heights and ergonomic working for employees. Using electric extensions, the platform width can be maximized, reducing the risk of falling.

Media Supply and Equipment

The work platforms are equipped with media connections such as electrical outlets and compressed air to facilitate the work process. Shelving and perforated sheet cladding provide space for work materials. Swiveling cross bridges ensure a transition between the two work platforms.

Safety and Flexibility

Optical and acoustic signals visualize the movements of the platforms. Access is via adjustable stairs on both sides, each with safety doors. Contact strips on the platform sides, distance sensors, and emergency stop controls on the platforms ensure additional safety. Product protection is guaranteed by impact protection.

Control and Limitation

Both stages are controlled independently and can be used in automatic or manual mode. The area of longitudinal movement can be individually selected. For this work platform, the operating range is approximately 20 meters.

Electrical Supply

The electrical supply is via a busbar system. The control cabinet is securely attached to the base frame and offers the operator good accessibility.

Conclusion

The innovative work platform offers measurable added value to the customer. Thanks to its adaptable properties, the assembly of roofs and the conversion of vehicles can be made more efficient. The ability to individually adapt to various vehicle types enables a smooth workflow and simultaneously protects the vehicles from damage. The flexibility in speed and height ensures ergonomic working, which increases productivity and employee satisfaction. With media connections and versatile equipment, the work process is further optimized. The work platform is thus a practical and standard-compliant solution that exceeds the specific requirements of the customer and represents clear added value in terms of efficiency and safety.

- Corporate certification: ISO 9001

- Corporate certification: ISO 14001

- Corporate certification: EN 1090

- Corporate certification: EcoVadis

- RoHS

- REACH

- The MUNK Group complies with a Code of Conduct

- The Supply Chain Act does not apply due to our size

- The materials used are listed in the technical specification

- Resource-saving production: own photovoltaic systems

- Energy-efficient consumption during production: LED lighting

- Repairability, durability and quality: 15-year warranty on series products made in Germany

- Recyclability: Our products are mostly made of aluminium, steel or wood and can be fed directly into the recycling process.

- Socially acceptable working conditions in production: fair wages, gender equality

- Economical and recyclable packaging: no use of polystyrene, predominantly use of wood and cardboard, small amounts of plastic

- No health hazards for the users

Custom access equipment: 5 stars for your safety

Trust in us as your competent partner in the field of individual access equipment solutions. We are industry leaders from analysis to conception and design to first-class after-sales service.

★ Analysis

We set standards in the evaluation of access equipment requirements. Our experts take sufficient time to understand your specific needs. After a thorough analysis, we will present you with a tailor-made design that is perfectly tailored to your individual circumstances. Rely on us to identify your challenges and solve them in an innovative way.

★ Concept

We are leaders in the planning of special designs. With creativity, technical know-how and a deep understanding of access equipment, we develop pioneering concepts. Our experienced team designs outstanding solutions that meet the highest safety standards and maximise your efficiency and ergonomics. Let yourself be impressed by our competence and innovative strength.

★ Design

We set the bar high in design. Our engineers and production planners have unique specialist knowledge and many years of experience in the field of access equipment. With the latest technologies and high-quality materials we realise your concept down to the smallest detail. Precision and quality are the first priority – for your special designs that meet the highest demands.

★ Production

In our modern production halls at our headquarters in Günzburg, we can implement your planning and wishes professionally and efficiently. Our specialists in access equipment, electronics and mechanics always have only one thing in mind: Quality that delivers what it promises. That's why every design, whether large or small, is manufactured with the highest quality and precision and thoroughly tested before shipment.

★ After sales

Our commitment does not end with the completion of the special design. We are unbeatable in after-sales service. With assembly, maintenance, testing and repairs, we ensure that your special design always remains in perfect condition. Our reliable team provides you with superior customer service and ensures that your satisfaction is first and foremost.

Special constructions

From decades of experience, we know that individual requirements require special solutions. That's why we are here to help you realize your custom construction.

Get inspired by our reference products and make your unique idea a success. We look forward to supporting your project with our expertise and dedication. Contact our competent team for more information and assistance.

With MUNK Group by your side, your custom construction becomes a reality: Safety. Made in Germany.

What we offer

- On-site consultation and project planning

- Custom development according to your requirements

- Precision manufacturing

- Functional and cost-effective access solutions

- Maximum workplace safety

- Fast delivery

- Compliance with all relevant German, English, and international standards and regulations, such as BetrSichV, DGUV regulations, Machinery Directive 2006/42/EC